Published

30 October 2022

Using DigitalGlassware® to Gain Deeper Insights

In a previous blog we saw how DigitalGlassware® from deepmatter® allowed Tobias in Basel to locate a reaction run by Hannah in Glasgow, and successfully replicate it in his own lab.

Katherine, an academic chemist in Toronto, has seen how easily reaction recipes and data can be shared and analysed using DigitalGlassware®, and has decided to try the platform for herself to compare multiple runs of her own reaction.

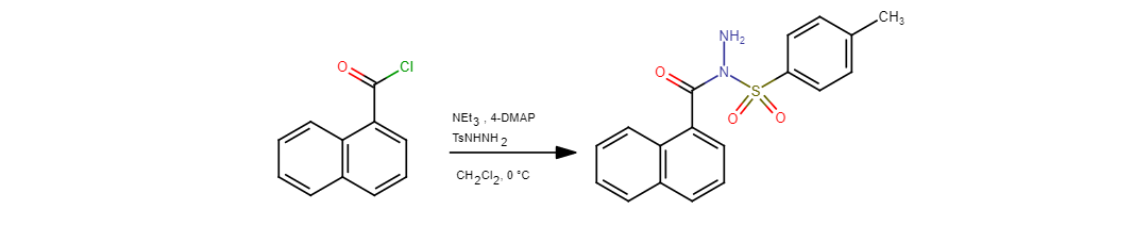

Katherine uses the RecipeBuilder component of DigitalGlassware® to create a digital version of a published organic synthesis: a condensation reaction to produce an N-acyl-p-toluenesulfonyl hydrazide, which can be converted to an aldehyde under mild conditions, without the use of oxidants or reductants (Org. Synth. 2018, 95, 276-288).

The scheme for the synthesis of N-(1-naphthoyl)-4 methylbenzenesulfonohydrazide

She then sets up her reaction using the unique DigitalGlassware® hardware. The EnvironmentalSensor and DeviceX sensors monitor conditions outside and inside the reaction vessel, and are connected to the internet using the DigitalController, which sends real-time data directly to Katherine’s cloud account as well as to the RecipeRunner app on her tablet.

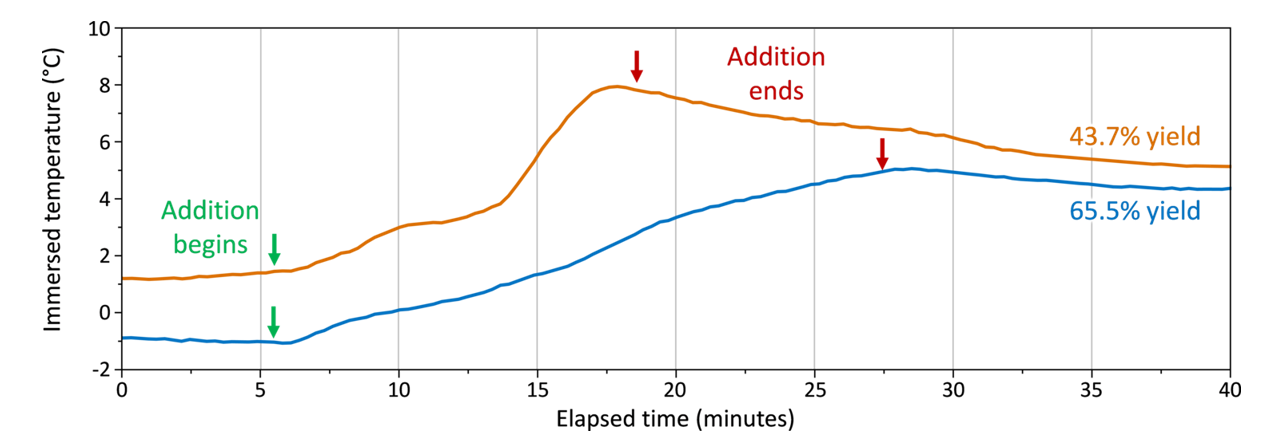

Katherine carries out the reaction twice, following step-by-step instructions on RecipeRunner. As she completes each procedure, a timestamp is recorded. The first run resulted in a yield of 43.7%, while the second was significantly improved at 65.5%. Curious about what could cause this difference, Katherine loads up both sets of data in the RunManager software. A look at the Operation Timeline reveals that the reagent addition step in her second run was considerably slower (20 minutes) than in her first attempt (13 minutes).

The DigitalController from deepmatter™ connects your reaction flask to the cloud.

The Operation Timeline of two runs of the same recipe in RunManager.

The data from the immersed temperature sensor of DeviceX also shows the effect of this more gradual addition process.

DeviceX immersed temperature sensor data for the 43.7% run (orange) and 65.5% run (blue)

Speculating that this more gradual addition might be responsible for the improved yield, Katherine repeats the reaction again, adding the reagent more slowly (this time over 22 minutes). The third run results in a very similar yield to the second, at 66.0%. Because DigitalGlassware® records every step of the reaction in real time, chemists can analyse reactions in greater detail than ever before, giving them a greater understanding of the factors that can maximise yields and reduce failure rates. In this instance, Katherine can modify the recipe to ensure that future users add the reagent more slowly.

You can see Katherine’s reaction data and explore the RunManager module here, and contact us here for further information. Remember to check back for regular blog updates that will show how DigitalGlassware® can work in your lab.